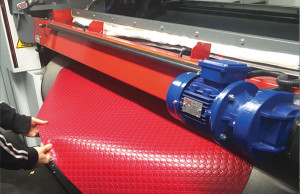

New concept of ironing:

Variable geometry machine.

ROTOMEC holds the patent of this system that allow to move the heated

cylinder in relation to the pressure cylinder, within precision of one tenth

of millimeter, modifying the contact geometry and the final result on the

ironing.

The machines offers also the advantage to work in open thicknesses with heated cylinder independently motorized, without felt. Opportunity to roll up the felt on heated cylinder. Working pressure extremely precise

read by load cells, without recourse of oil-dynamic control units.